Renoveerimise tehnoloogiate ja ehitusfüüsika uurimisrühm

Renovation technology and building physics research group

Introduction

This research group was established 2012 as Nearly zero energy research group, now focusing to climate resilient renovation and future-proof zero emission buildings. Professor Targo Kalamees, senior researchers Endrik Arumägi, Simo Ilomets, Paul Klõšeiko are responsible for teaching of building physics and renovation technology subjects such as building envelope components thermal and moisture performance, hygrothermal modelling, moisture safety, renovation methods and prefabrication to civil engineers, architects, and building conservators. With 10 active PhD students and some senior researchers and postdocs, the number of personnel is about 20 persons. With other groups, there is intensive cooperation with prof. Ergo Pikas to incorporate construction management and economics competence, with prof. Aime Ruus on renovation technology, with prof. Kimmo Lylykangas on architecture and urban planning, and prof. Ivar Talvik on structural design.

Competence

ZEB research group represents key competences and teaching responsibilities in the following domains:

- Building physics

- Building envelope assemblies

- Hygrothermal modelling

- Moisture safety of buildings

- Prefabricated renovation

- Climate resilient renovation and future-proof of zero emission buildings

Research topics

The main research topics have been focused to hygrothermal performance and resilience of building envelope structures and application of prefabricated renovation technology. Moisture problems, construction time moisture management, durability and moisture safety, but also lifecycle cost, carbon footprint, indoor climate and energy analyses have been most common topics in many studies. The research infra includes the NZEB technological research facility as a full-scale test site and climate chambers for controlled laboratory experiments.

The group has had a leading role in the preparation of Estonian Long Term Renovation Strategy 2020-2050 and boosting its implementation with industrialised renovation methods. The group has contributed through many projects to Estonian NZEB model solutions and energy calculation methodology development that are currently in use. Pioneering work by the group is the execution of the first prefabricated renovation projects of multifamily apartment buildings in Estonia and wide cooperation with local wooden house manufactures to support product and competence development resulting in industrialised renovation method piloting in large scale and inclusion to Estonian ongoing KredEx renovation support scheme with explicit technical and financial conditions.

Some examples of research topics and outcomes:

- Prefabricated insulation elements for offsite renovation.

- Circularity in construction and renovation of buildings.

- Renovation of Estonian building stock and developing its long-term resilience

Interior thermal insulation. - Positive energy neighbourhoods and districts.

- Renovation strategy tool for municipalities and real estate owners.

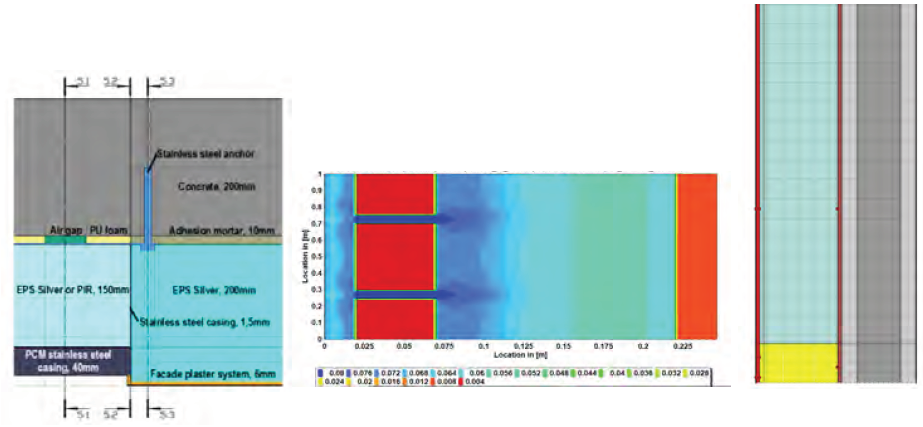

- Energy activated external thermal Insulation composite system.

- Carbon footprint and environmental impacts of buildings.

- Using BIM to increase energy performance of buildings.

- Indoor and outdoor hygrothermal loads for design of building envelope.

Research infrastructure | Short description |

NZEB technological test | Rooms of 100 m2 test building can simulate office, school or a dwelling. It is equipped with HVAC and automation systems and has been used to study heating, ventilation and cooling systems and components performance in real operation. Facades can be replaced that is used for building physics studies. |

CLT test facility | This 20 m 2 test building can simulate various indoor hygrothermal loads to study hygrothermal performance of cross laminated timber structures. |

Multipurpose climatic chambers | Interior and exterior climate chambers enable to study building envelope components and HVAC equipment at controlled climatic conditions. Some examples are frost resistance measurements of interior insulation systems and frost formation measurements of heat exchangers of ventilation units. |

Outdoor and indoor climate chambers with outdoor wind driven rain, solar radiation, temperature and RH, and indoor temperature and RH control

Measurements of novel building envelope and service systems in full scale test facilities

Equipment to measure a whole building and structure specific air leakage, and hygrothermal properties of materials including cup test, pressure plate apparatus, vacuum saturation kit, psychrometric water potential meter, drying test and others

Examples of 2 dimensional hygrothermal models, created in Delphin software